European Solar Technology Leaders

Back-Contact Technology by TNO

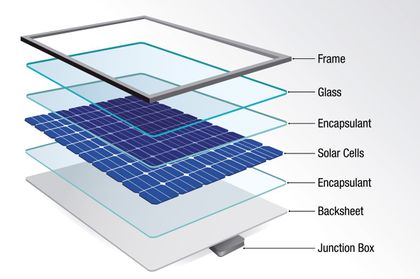

The module design is based on back-contact interconnection, an industrially proven concept that was developed in the Netherlands by ECN (now part of TNO). Back-contact modules can realise superior power outputs because of their low cell-to-module loss factor, their superior robustness against thermo-mechanical stresses and their inherent capacity to dissipate heat, which allows them to ‘run cooler’ than conventional tab-string modules. Their form-factor is more flexible than that of conventional modules, which makes back-contact modules easier to integrate, and facilitates desirable aesthetic designs.

ZEBRA Technology by ISC Konstanz

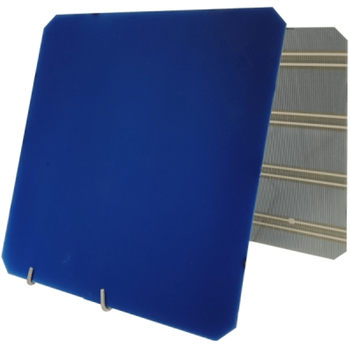

The solar cells in the module that drive its high performance are based on the ‘ZEBRA’ IBC (Interdigitated Back Contact) technology developed by ISC Konstanz, which is the lowest cost IBC technology reaching efficiencies up to 24% in production. The current technology reaches voltages above 700mV without the need of passivating contacts.

Large scale production by Energyra Europe

Following the research and certification phase, large-scale production of the IconIQ solar module will start in Zaandam mid 2021. But not only the production line is a feat of European high-tech. With a strong focus on the implementation of technology and know-how from the EU, and above all the responsible use of raw materials, Energyra has built a strong relationship with leading knowledge institutions, material suppliers and machine builders in Europe.